Top Industrial Automation Jobs for Freshers in the Manufacturing Sector

1. Automation Engineer

Automation Engineers play a crucial role in designing, implementing, and optimizing automated systems within the manufacturing sector. They focus on creating the software and hardware solutions necessary to automate machinery and production processes, enhancing efficiency and reducing operational costs. Freshers aspiring to become Automation Engineers should focus on developing their skills in programming languages such as Python, C++, and ladder logic, alongside gaining a good understanding of PLC (Programmable Logic Controller) systems.

2. Control Systems Engineer

Control Systems Engineers are responsible for developing and maintaining control systems used in manufacturing processes. This role involves designing and implementing feedback systems that maintain desired levels of operation, such as temperature, pressure, and speed. For freshers, gaining knowledge in control theory, SCADA systems, and experience with sensors and actuators will be beneficial. Familiarity with software such as MATLAB can also be an asset.

3. Robotics Technician

The role of a Robotics Technician involves working directly with robotic systems on the factory floor. These technicians are responsible for setting up, maintaining, and troubleshooting robotic units used for various manufacturing applications like welding, assembly, and packaging. Fresh graduates with a background in mechanical or electrical engineering, who have hands-on experience in robotics, will find opportunities in this field. Skills in programming robotic systems and understanding robotic kinematics are essential.

4. Quality Assurance (QA) Engineer

QA Engineers specialize in ensuring that automated systems function as intended. They develop testing protocols to identify defects and ensure compliance with industry standards. Freshers can enter this field by leveraging their attention to detail and analytical skills, focusing on learning software testing methodologies and tools relevant to automation. Familiarity with statistical quality control tools can also enhance employability in this competitive environment.

5. Process Automation Technician

Process Automation Technicians focus on optimizing manufacturing processes through automation. They ensure that production systems operate efficiently and smoothly by monitoring systems, diagnosing issues, and implementing solutions. Fresh graduates should emphasize gaining knowledge about industrial process control and being proficient in HMI (Human-Machine Interface) software. Certifications in relevant tools can bolster a fresher’s resume significantly.

6. Field Service Engineer

Field Service Engineers are responsible for installing, maintaining, and repairing automated equipment in various manufacturing plants. They must troubleshoot electrical and mechanical failures, ensuring that manufacturing processes are not interrupted. Freshers should develop strong problem-solving skills and gain hands-on experience through internships or co-op programs. Good communication and customer service skills are also imperative for this client-facing role.

7. Manufacturing Systems Analyst

Manufacturing Systems Analysts evaluate current manufacturing processes to identify areas for improvement through automation. They use data analysis and simulation tools to assess production efficiency and effectiveness. Freshers will benefit from a strong foundation in data analytics, experience with ERP (Enterprise Resource Planning) software, and proficiency in statistical analysis. Familiarity with Lean manufacturing principles is advantageous.

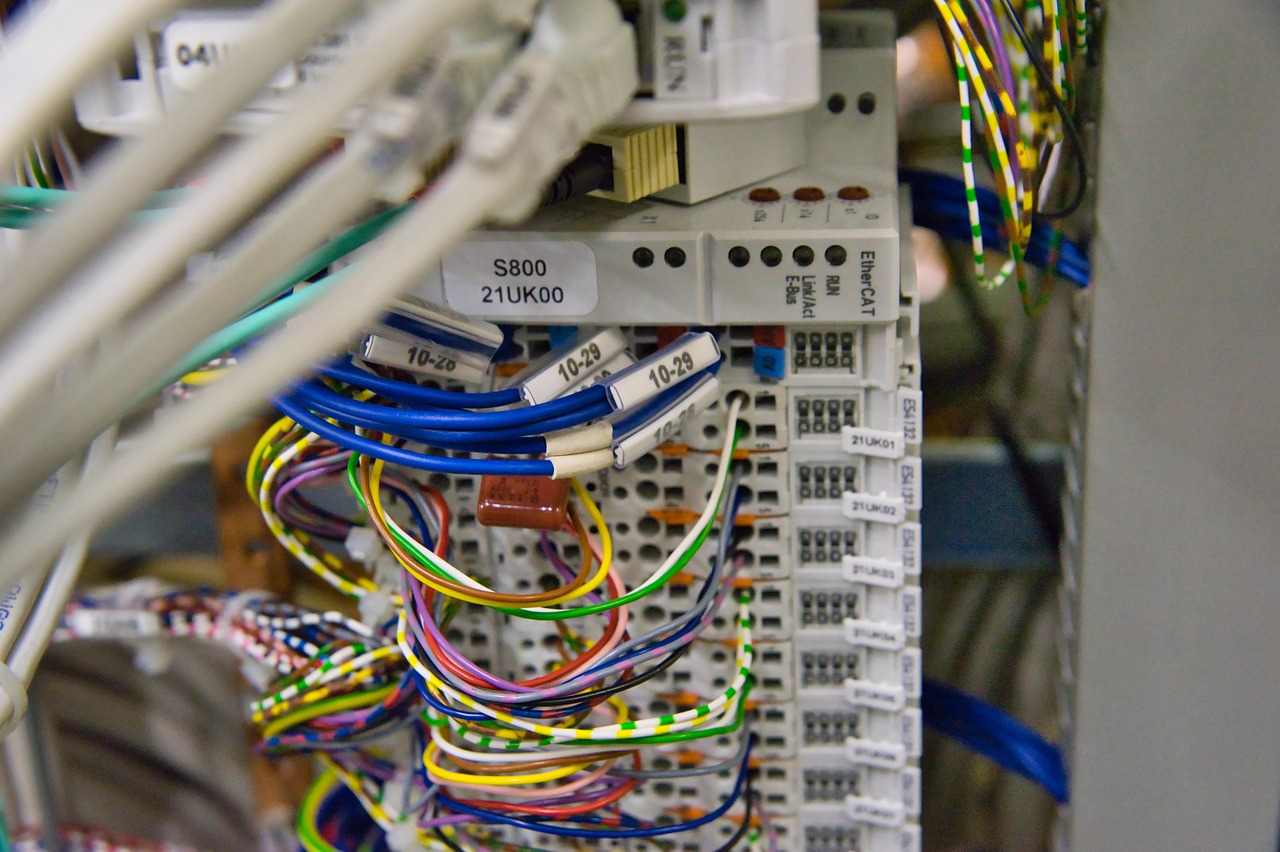

8. Electrical Technician

Electrical Technicians play a vital role in maintaining and repairing the electrical components of automated systems. This role requires strong technical knowledge and practical skills in electrical systems and circuitry. Freshers should focus on gaining hands-on experience through technical training or apprenticeships while learning about industrial electrical systems, safety standards, and applicable codes. Certifications can help freshers stand out in this area.

9. Software Engineer (Automation)

Software Engineers who specialize in automation develop the software systems that control manufacturing robots and machinery. They must be proficient in programming languages and understand the industrial automation landscape. Freshers should work on enhancing their coding skills, particularly in languages such as Java, C#, and Python, and familiarize themselves with software development methodologies such as Agile or DevOps. Exposure to machine learning can also provide an edge.

10. Maintenance Planner

Maintenance Planners are responsible for overseeing the maintenance schedule of automated systems, ensuring that machinery operates smoothly and efficiently. They analyze downtime data and prioritize maintenance tasks to minimize production disruption. Freshers should focus on learning preventive maintenance strategies and developing time management skills. Knowledge of CMMS (Computerized Maintenance Management System) software can be a key differentiator in this role.

11. Industrial Designer

Industrial Designers in automation focus on creating ergonomic and efficient systems and machinery that incorporate automation features. They work closely with engineers and manufacturers to optimize product design for usability and production efficiency. Fresh graduates should build skills in CAD software, such as SolidWorks or AutoCAD, and gain an understanding of user experience design principles.

12. System Integrator

System Integrators specialize in integrating various automation technologies and systems to create cohesive manufacturing solutions. They design, install, and configure automation systems to ensure they work well together. A background in electrical engineering or computer science is beneficial for freshers looking to enter this role. Skills in project management and knowledge of various automation technologies, such as PLCs and DCS (Distributed Control Systems), are crucial.

13. Data Analyst

Data Analysts in industrial automation analyze production data to improve processes and identify areas for operational enhancement. They utilize statistical methods and visualization tools to derive actionable insights from data trends. Freshers should focus on developing strong analytical skills, proficiency in Excel, and experience with data visualization software such as Tableau or Power BI. Understanding big data and IoT (Internet of Things) applications will also increase job prospects in this area.

14. Safety Engineer

Safety Engineers ensure that automated manufacturing environments are compliant with health and safety regulations. They assess risks associated with manufacturing processes and recommend necessary safety measures. Fresh graduates should familiarize themselves with safety management systems and regulatory guidelines. Certifications like NEBOSH or OSHA are often beneficial and may set a fresher apart from other candidates.

15. Technical Sales Engineer

Technical Sales Engineers combine their technical knowledge of automation systems with sales skills to assist manufacturers in purchasing the right automated solutions. They serve as a bridge between the engineering team and clients. Fresh graduates with strong communication and interpersonal skills, combined with a solid understanding of automation technologies, will be well-suited for this role. Exposure to sales techniques and customer relationship management could be beneficial.

Industry insights indicate a growing demand for automation professionals as companies increasingly adopt technologically advanced solutions. Freshers who focus on honing both their technical skills and interpersonal abilities stand a greater chance of excelling in this dynamic landscape.